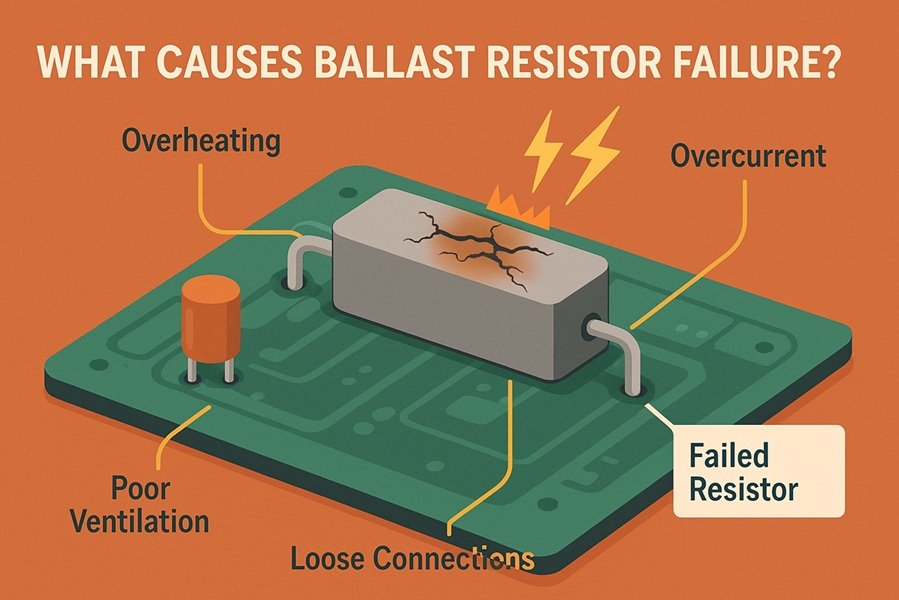

What Causes Ballast Resistor Failure

How Ballast Resistors Impact Ignition Systems

Ballast resistors serve an important function in ignition systems. During engine startup, high voltage is required to permit sufficient current to flow to the ignition coil; therefore, the ballast resistor is bypassed to facilitate maximum current supply to the coil. However, once the engine is running, their acting is drastically shifted: while in operation, they reduce current to protect both coil and other mechanics from heat overheating and getting worn out very fast. This property of ballast resistors in a dual-mode operation makes for proper smooth starting and operating of engines.

Signs of a Failing Ballast Resistor

When your ballast resistor begins to fail, several telltale symptoms may become evident. These include difficulty starting the engine in cold weather conditions, inconsistent engine performance and frequent stalling; in some instances drivers may notice decreased fuel efficiency or an increase in engine misfires. Left unattended, failing ballast resistors can lead to more severe ignition system issues that leave drivers stranded; regular maintenance and prompt attention paid to these symptoms could help protect against more extensive damage to their ignition systems and help prevent more extensive damages being done to their ignition systems.

Electrical Issues Leading to Failure

Voltage fluctuations and their effects

Voltage fluctuations can wreak havoc on ballast resistors, leading to their early failure and contributing to unexpected electrical stress on resistors. Voltage spikes may overwhelm its capacity causing it to overheat excessively or melt or burn out completely; conversely voltage drops may limit current flow compromising performance and potentially damaging connected components.

Short circuits damaging the resistor

Short circuits pose a severe threat to ballast resistors. When a short occurs, it creates a path of least resistance, bypassing the ballast resistor and allowing an excessive amount of current to flow. This sudden surge can cause the resistor to overheat rapidly, leading to thermal damage or complete failure. Sometimes due to its immense heat output during short circuits the resistor might even catch fire and pose serious safety risk.

Overloading the electrical system

Overloading the electrical system is another common cause of ballast resistor failure. This typically occurs when additional electrical components are added to the vehicle without proper consideration of the existing system’s capacity. As the electrical load increases beyond the resistor’s designed limits, it struggles to regulate the current effectively. This sustained overload can cause the resistor to operate at higher temperatures than intended, accelerating wear and ultimately leading to failure. Regular maintenance and careful consideration of electrical modifications are crucial in preventing such overload-related issues.

Environmental Factors Causing Resistor Damage

Extreme temperature effects

High temperatures can significantly impact ballast resistors, causing them to expand and potentially crack. Conversely, extreme cold can render them brittle, leading to fractures under sudden fluctuations. Over time these thermal stresses weaken its internal structure, diminishing effectiveness and lifespan over time.

Moisture and corrosion

Moisture poses an ongoing threat to ballast resistors. Water infiltration can lead to short circuits, accelerate corrosion of metal components and compromise their insulation properties. In coastal regions, salt air further compounds this problem by creating an electrical conductive surface on top of resistors which undermines their insulation properties and compromises their insulation capabilities.

Vibration and physical stress

Constant vibration from engine operation can gradually loosen connections and cause microfractures in the resistor. This is particularly problematic in older vehicles or those driven on rough terrain. Over time, these small damages accumulate, leading to complete failure of the ballast resistor.

Dust and debris accumulation

Over time, dust and debris may settle onto resistors, acting as an insulating layer and blocking heat dissipation. This trapped heat causes higher than intended operating temperatures for the resistor, speeding wear-and-tear wear rates and potentially leading to premature failure or even short circuiting resulting in immediate resistor failure.

Conclusion

There are many reasons behind ballast resistor failure, from electrical and environmental to manufacturing-related problems. Vehicle owners and mechanics alike ought to understand these factors to avoid sudden breakdowns during optimization of ignition system performance.

It will greatly reduce ballast resistor failure if you perform a consistent check and maintenance of your vehicle’s electrical parts throughout the life of the vehicle. Signs that the ballast resistor needs to be looked at by a qualified mechanic include starting problems and rough running or unsteady performance by the engine. If problems are spotted early while relatively harmless, action can be taken to prolong its life and maybe save some money in costly repairs later on.